Introduction to Aircraft Engines | Case Study

Introduction to Aircraft Engines Case Study by Wael Bakdash

The aviation industry is one of the most important industries in human life and it’s also one of the fastest-growing sectors worldwide (Levrageedu, 2021). Although it’s sensitive to global shocks, it recovers back again to normal conditions over time. This is because the demand for air travel both cargo and passenger flights is very high and keeps increasing every year. Airplanes of different kinds are used to fulfill the demand for people, these aircraft are powered by a mind-blowing, masterpiece of engineering machines called the engines. Just like a human heart, you can’t survive without it, the engine is the aircraft’s heart that it can’t fly without.

An aircraft engine is a very important machine that we should understand how it works and what are the different types of aircraft engines used around the world, and that is why it came to my interest to explain this topic. In this report, I will briefly explain the increase in sales of jet engines which explains the increase in demand for air travel, proof that air travel is the safest, the requirements that an engine is expected to deliver, explain how an aircraft engine works in general, and introduce the different types of engines that are used on aircraft which I will discuss in details.

Before we start with our report, did you know that an aircraft can fly with just one engine? It has been tested on the Boeing Dreamliner and it showed that it can fly for a 330 minutes using one engine which is roughly five and a half hours, similarly, most models of other manufacturers build their aircraft to fly with just a single engine. In fact, aircraft that are expected to fly over oceans, long-distance routes, and inhabitant areas should be certified by the FAA for Extended-range Twin Operations (ETOPS) which is a certification of how of long an aircraft fly with a single engine. Moreover, most aircraft are capable to fly for longer distances with no engine at all thanks to their glide ratio, for example, a Boeing 747 can glide for two miles for every 1000 feet above the ground which is more than enough to land safely.

Research:

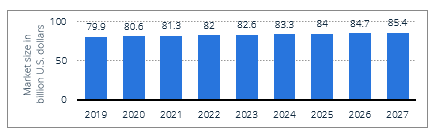

Aircraft Engine Market Size:

The market size of the commercial aircraft engine market from 2019 to 2027 is expected to increase annually at a steady pace which shows us that demand for them is increasing every year, which also shows that air travel demand is increasing because no one will buy and build an aircraft with its engines if the demand for them is low. So since demand for air travel increases, the demand for engines also increases. The following histogram explains for us visually the size of the commercial aircraft engine market from 2019 to 2027 (in billion U.S. dollars):

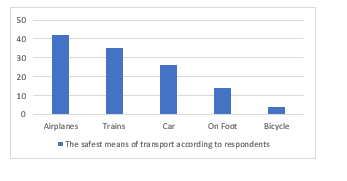

Safest Way of Transportation?

According to (Joanna Hernik, ResearchGate), the safest mean of transportation is air travel. This is proven by a survey that was conducted with a group of people to see what is the safest mean of transportation, results returned unsurprisingly showing that air travel was the one with the highest score. One of the most important factors that contribute to this repetition is the advancement in technologies used in the aircraft and most importantly their engines. Here is a visual representation of the results:

What is Expected from an Aircraft Engine?

There are some requirements that an aircraft engine is expected to meet. These requirements include:

- Power and Weight: If the specific weight of an aircraft engine is decreased, the useful load and the performance of this aircraft will increase. Thus, every extra pound of weigh added will reduce the engine’s performance. The improvements in reducing aircraft weight engines through better designs and metallurgy resulted in reciprocating engines with a much improved power-to-weight ratio (specific weight).

- Fuel Economy: Fuel consumption for gas turbines is measured in (lb/hr) divided by thrust (thrust-specific fuel) and for reciprocating engines is measured in (lb/hr) divided by brake power (brake-specific fuel). Fuel economy is better at lower speeds for both the reciprocating and turboprop than turbofan or turbojet engines. At higher speeds however, the turbofan and turbojet becomes more efficient than the reciprocating and turboprop that is because of the loss in the propeller efficiency at higher speeds.

- Durability and Reliability: An aircraft engine is reliable when it can perform at the specified ratings in varying flight altitudes and weather conditions. Durability is the expected engine lifetime obtained while maintaining the desired reliability. Engine must be continuously maintained through periodical and preflight inspections and strict observance of the operating limits established by the engine manufacturer in order to make engine failure a rare occurrence.

- Operating Flexibility: That is the ability of the engine to give the expected performance at all speeds from idle to full power. It also must perform efficiently through all variations of atmospheric encountered through its operation.

- Compactness: An engine shape and size shall be as compactable as possible to allow proper streamlining and balancing of the aircraft. The more elongated and spread out an engine, the more difficult it will be to keep the specific weight within allowable limits.

- Powerplant Selection: Depending on how will a manufacturer will want its aircraft to fly, different powerplants are used. For example: if you are planning your aircraft to fly at altitudes above 30000ft turbo-supercharged reciprocating engine may be chosen because it is capable of maintaining rated power to a high altitude. However, if you are planning your aircraft to be used at low altitudes reciprocating engine maybe chosen because of its excellent efficiency and relatively low cost.

How do Jet Engines Work in General?

The aircraft engine works with the physics concept of Conservation of Momentum, which is mass multiplied by velocity. A jet engine uses this concept by taking a mass of air in the front at a slow speed and pushing this air out in the back a lot faster. The momentum going into the front of the engine is smaller than the one going out, thus the engine generates forward thrust. We can see a virtual animation in the right about how thrust and momentum are related.

Now we need the air that comes in to move way faster when it comes out, to do so aircraft engines also use two important physics concepts Venturi Effect and the Ideal Gas Law. The venturi effect or tube is a rigid tube with one end larger than the other and what goes through it must go out. Air flows constantly through it until it reaches to the small cross-section area where air gets squeezed and moves faster. The venturi effect explains why aircraft engines are big at the front and very small in the middle. Ideal Gas Law relates the temperature to pressure, volume, and amount of air. Hotter gasses will take up more volume or appear bigger. Now, combining the conversation of momentum, the venturi effect, and ideal gas law we can understand how jet engines generate thrust.

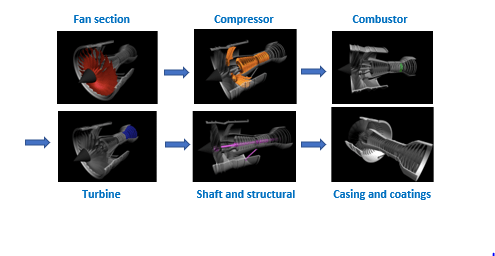

The fan and a compressor in the front of the engine suck in air increasing the mass of air in the engine while at the same time keeping the intake velocity low. Air is then ignited with fuel which leads to expand in the air’s size and volume. The air will then leave the engine with a higher velocity generating thrust. These steps could be summarized by “suck-squeeze-bang-blow”. You can see below what an engine looks like from the inside:

What are the Common Types of Engines Used?

There are many different types of jet engines used worldwide, however, these are the five most commonly used all around:

1. Turboprop Engines

2. Turbojet Engines

3. Turbojet Engines

4. Turbofan Engines

5. Ramjet Engines

Discussion and Explanation about the Common Jet Engines:

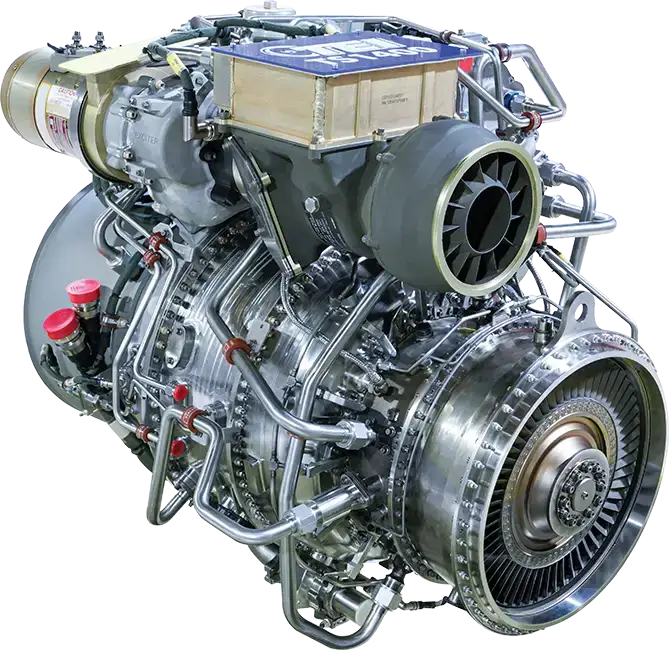

Turboprop Engines:

- A turboprop is a turbojet engine that uses a gearing system to connect to the aircraft propeller. The gearbox is used to slow down the spinning shaft allowing the gear to connect to he propeller.

- These engines are fuel-efficient in mid-range altitudes and rotate at mid-range speeds ranging between 250 and 400 knots. However, due to their weight, the gearing system could break down quickly.

- The engine comprises a combustion chamber which contains pressurized air and gas, a turbine, and a compressor which all work together to run the turbine.

- In order to make the aircraft stable at high altitudes, these engines are equipped with many blades.

- These blades are scimitar-shaped and the edges of their tips are swept back for efficiency at high flight speeds. These types of engines are usually called propfans.

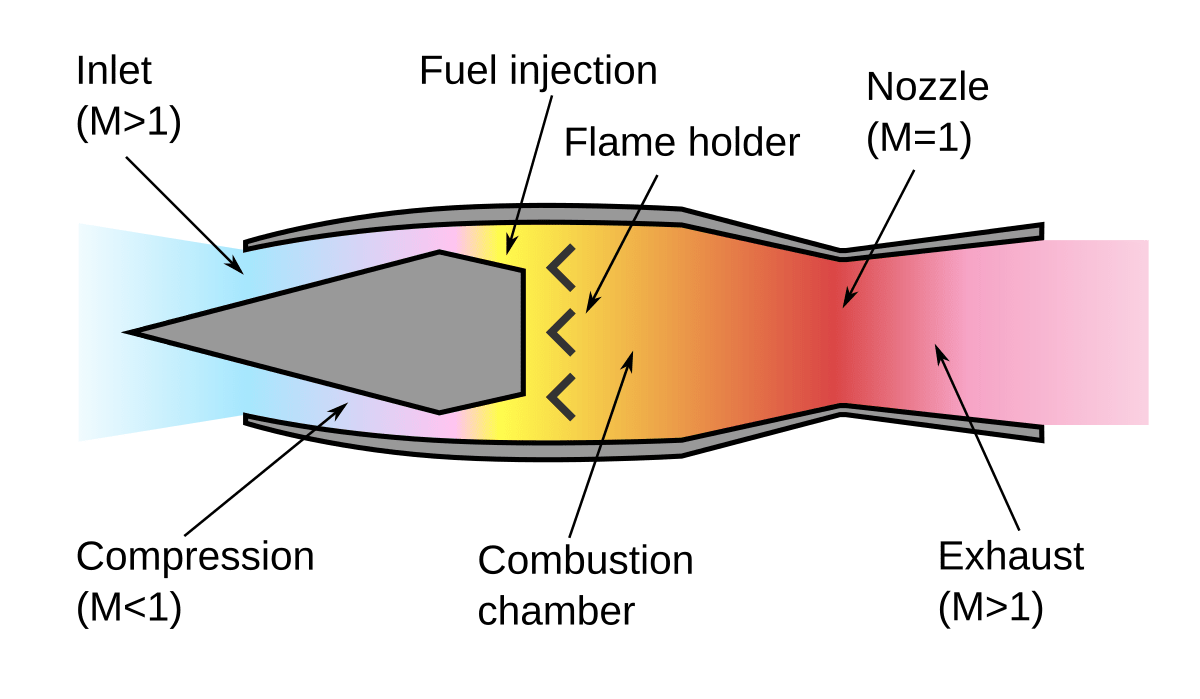

Turbojet Engines:

- The idea here is simple, enlist takes the air from the rear side and then compresses it in the compressor. Fuel is added in the combustion chamber to ignite with the air raising the fluid mixture temperature. Hot air is then pushed in the turbine that rotates the compressor. Here, the pressure should be twice the pressure in the atmosphere. Excessive pressure then moves to the nozzle that generates streams, which creates thrust.

Air Intake: a tube attached to the front of the engine. Its role is to direct air into the blades of the compressor, it can also help minimize the loss of air into the engine at low speeds. Even it can slow the flow at high speeds. No matter the speed of the aircraft the flow of air should always be subsonic.

Combustion Chamber: here the role is to combine high pressure to ignite the mixture.

Compressor: its role is to compress the air as it passes each stage of compression. It consists of a series of fans, each fan contains small blades.

Exhaust: Air mixture and burned fuel exit the engine through the exhaust nozzle. Thus, thrust is produced as the compressed air pulls out of the front side of the compressor.

Turbine: series of fans each with blades attached to the shaft to rotate it. Its role is to absorb energy as the high-speed air flows through the compressor.

Turboshaft Engines:

- It’s a form of gas-powered turbine operating in the same way a turboprop work. However turboshaft don’t use propellers, instead they are used in helicopters to provide power to the rotor.

- They are designed in a way in which the speed of the rotor rotate independently of the gas generator’s speed, allowing the rotor to remain constant even when the gas generator’s speed decline.

- Their power is mainly used to rotate the turbine instead of producing thrust. Shafts here are used to connect the transmission to the rotor blade.

- The role of the rotor blade transmission is to transfer rotation from the shaft to the rotor blade.

- The downside is that their gear system is complex and breaks down easily.

- These engines take their power from the conversion of high-speed gasses into mechanical power to run the turbine, compressor, and other equipment. The shaft attached to the turboshaft engine drives both the aircraft propeller and rotor blade transmission of a helicopter.

- A reduction gearbox is used to propel the aircraft forward.

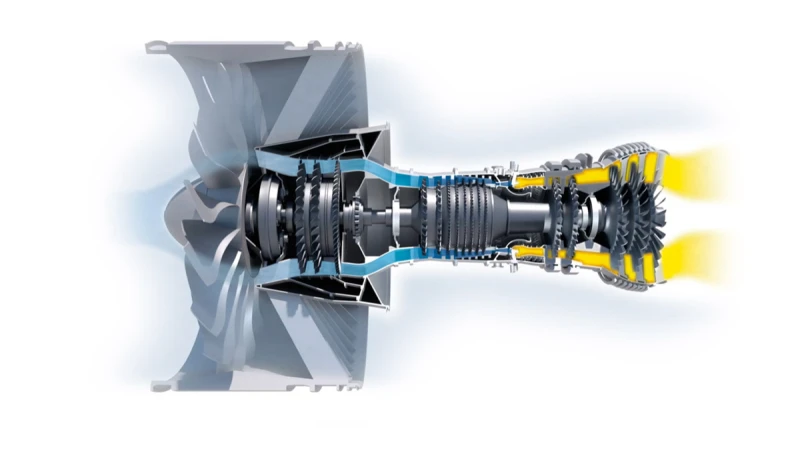

Turbofan Engine:

- Most of the airflow around the exterior of the engine is used to give the plane more thrust even at low speeds and keep the aircraft quiet.

- These engines are used by most airliners today.

- Small percentage of the air that passes through the turbofan engine reaches all the way to the combustion chamber.

- Rest of the air passes through a low-pressure compressor or fan, where it get mixed with gas or get ejected. The idea here is to achieve higher thrust while maintaining the same level of consumption.

Turbofans are upgraded versions of turboprops. They work the same as turbojet engines, but it has a ducted fan in the front. The fan cools the engine, creates additional thrust, and lowers the noise of the aircraft engine.

Turbofan aircraft engines are both quieter and more fuel-efficient than turbojets.

Ramjet Engines:

- Lightest types of engines with no moving components.

- It operates in the same way as a turbojet, however it doesn’t have rotating parts.

- Ramjets do not develop static thrust, it generates little thrust below the speed of sound.

- Aircrafts using ramjet engines require assistance during take-off, for instance being carried by another aircraft.

- Most aircraft that use these engines are space vehicles and several guided-missile systems.

Conclusion:

Jet engines are mind-blowing machines, many think that they are a big source of air pollution, but what most doesn’t know is that these machines just contribute to less than 2-3% of global CO2 emissions whereas road traffic contributes to 10%.

Engine are used to allow the airplane to move forward with a great force that is produced by thrust. Engines are very important, and in order to have the best out of them an airliner shall keep continuous checks on them as recommended from the manufacturer to avoid any damage on them that could lead to dangerous malfunctions threating the life of everyone onboard and even outboard or them failing mid-flight.

References:

- https://aerocorner.com/blog/types-of-aircraft-engines/

- https://ismswansea.com/home/jet-engine/

- https://ismswansea.com/home/jet-engine/

- https://www.aircraftsystemstech.com/2017/04/aircraft-engines.html

- https://www.researchgate.net/figure/The-safest-means-of-transport-according-to-respondents-own-study_fig4_328662678

- https://www.travelandleisure.com/airlines-airports/airplane-facts?slide=b0e68ba5-566a-481c-a611-f4d3f4feb1a1#b0e68ba5-566a-481c-a611-f4d3f4feb1a1

- https://youmatter.world/en/plane-or-cars-which-means-of-transport-pollutes-the-most/